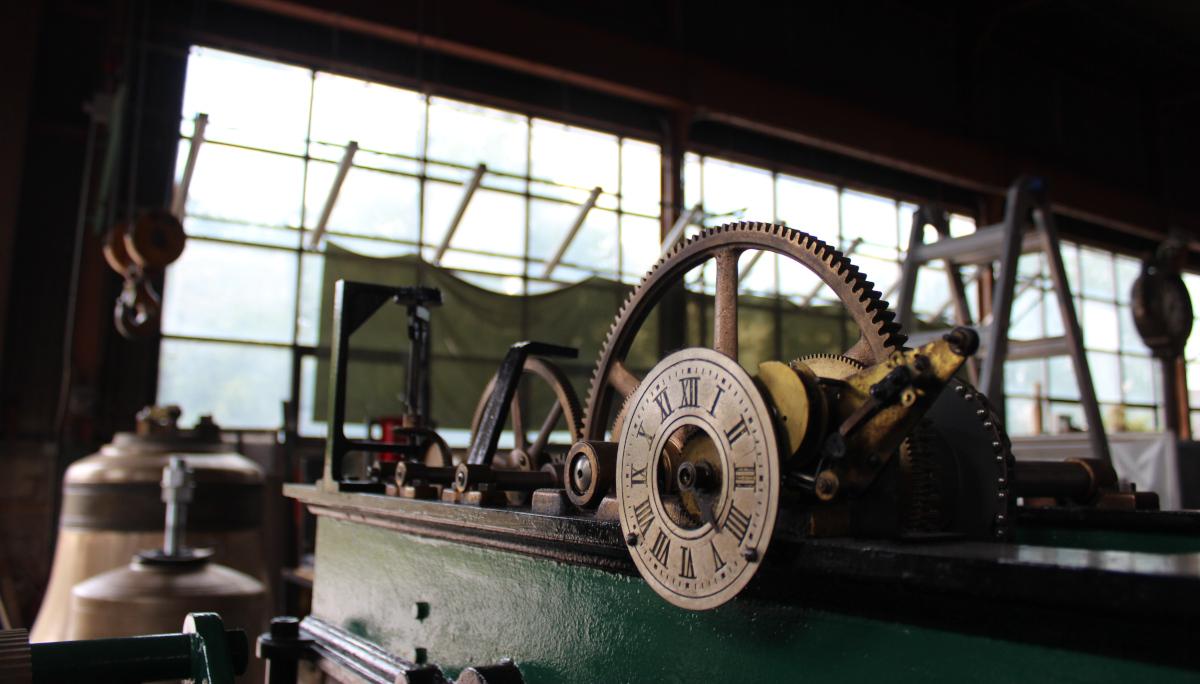

Guilloché dials begin by hand turning a fine silver disc in a rose engine. The pattern is determined by programming the engine with rosettes, phasing, and stepping over.

Finely ground enamel is washed and dried to remove impurities. A thin layer of enamel is sifted onto the turned dial.

The enamel is built up layer upon layer. Each layer is fired at about 1400 degrees Fahrenheit in the kiln. The enamel grains melt creating a smooth surface that is fused to the silver dial blank.

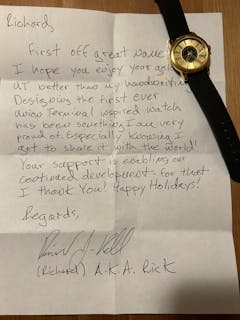

Watch designer Rick Bell & AWCI Certified watchmaker Jordan Ficklin at the Union Terminal.