Cloisonné dials begin with a pure silver dial blank to which a thin layer of clear enamel is applied.

A design is sketched on the blank and thin silver wires are formed to create cells or "cloisons" in which the enamel can be applied. Each silver wire is only 0.08mm thick and are bent by hand to create the design.

Finely ground enamel is washed and mixed with water so that it can be applied to the dial using a fine brush.

The cells are filled with various colors to create shading, gradations, and to bring the image to life.

The enamel is built up layer upon layer. Each layer is fired at about 1400 degrees Fahrenheit in the kiln. The enamel grains melt creating a smooth surface that is fused to the silver dial blank.

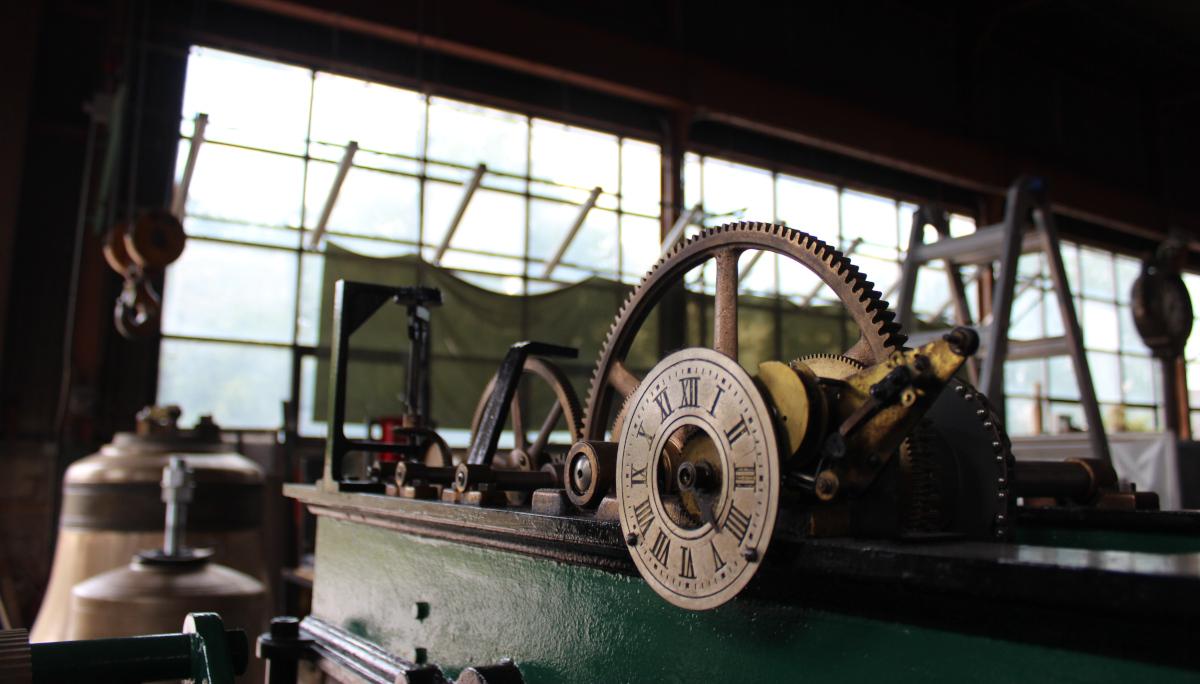

Watch designer Rick Bell & AWCI Certified watchmaker Jordan Ficklin at the Union Terminal.